Introduction

Diesel fuel storage tanks are essential for industries such as transportation, agriculture, construction, and emergency power generation. Proper storage ensures fuel quality, prevents contamination, and minimizes safety risks. This article explores different types of diesel fuel storage tanks, safety considerations, and best practices for maintenance.

Types of Diesel Fuel Storage Tanks

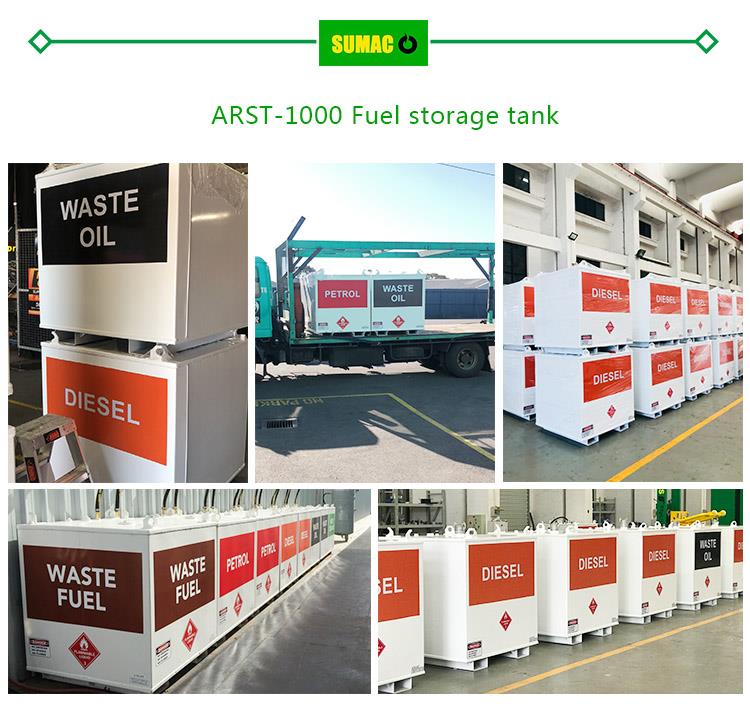

1. Above-Ground Storage Tanks (ASTs)

- Common Materials: Steel, polyethylene, or fiberglass.

-

Advantages:

- Easy to install and inspect.

- Cost-effective compared to underground tanks.

- Suitable for both small and large-scale storage.

-

Disadvantages:

- Vulnerable to extreme weather and UV degradation (for plastic tanks).

- Requires secondary containment to prevent spills.

2. Underground Storage Tanks (USTs)

- Common Materials: Steel with corrosion-resistant coatings or fiberglass.

-

Advantages:

- Saves space and reduces fire hazards.

- Less affected by temperature fluctuations.

-

Disadvantages:

- More expensive to install and repair.

- Strict environmental regulations to prevent leaks.

3. Portable Diesel Tanks

-

Types:

- Jerry cans (5-20 gallons) – Ideal for small-scale use.

- Intermediate Bulk Containers (IBC totes, 100-500 gallons) – Used in construction and agriculture.

- Mobile fuel trailers (500+ gallons) – For remote job sites.

-

Advantages:

- Easy to transport and refill.

- Often include built-in pumps and meters.

4. Double-Walled & Bunded Tanks

- Design: Features an outer layer to contain leaks.

-

Best for:

- High-risk environments (e.g., near water sources).

- Compliance with EPA and OSHA regulations.

5. Subbase & Modular Tanks

-

Used in:

- Backup power systems (e.g., hospitals, data centers).

- Military and remote operations.

-

Advantages:

- Can be installed below equipment for space efficiency.

- Often include integrated filtration and monitoring.

Key Safety & Maintenance Practices

1. Preventing Contamination

- Use high-quality filters to remove water and particulates.

- Keep tanks sealed to prevent moisture and microbial growth (diesel bug).

2. Fire & Spill Prevention

- Store tanks away from ignition sources.

- Install spill containment berms or secondary walls.

- Follow NFPA 30 (Flammable Liquids Code) guidelines.

3. Regular Inspections

- Check for rust, leaks, and structural damage.

- Monitor fuel quality (color, smell, sediment).

- Test tank integrity every 5-10 years.

4. Compliance with Regulations

- EPA rules (40 CFR 280 for USTs).

- OSHA standards for workplace safety.

- Local fire codes for tank placement and capacity.

Innovations in Diesel Storage

- Smart Tank Monitoring: Sensors track fuel levels, temperature, and leaks in real time.

- Eco-Friendly Materials: Polyethylene tanks with UV protection for outdoor use.

- Automated Fuel Management: Cloud-based systems optimize refueling schedules.

Conclusion

Choosing the right diesel fuel storage tank depends on capacity needs, location, and regulatory requirements. Whether using above-ground, underground, or portable tanks, proper maintenance and safety measures are crucial for long-term efficiency and environmental protection.